Metal Injection Molding (MIM) combines the shaping capability of plastic injection molding and the material flexibility of the conventional powder metallurgy to offer cost effective solutions for highly complex part geometries.

MIM is now a preferred manufacturing method for the mass production of small size, intricate geometry components of varieties of materials, achieving close to 98% of the wrought material properties at much reduced cost in comparison with conventional machining, investment casting or precision stamping.

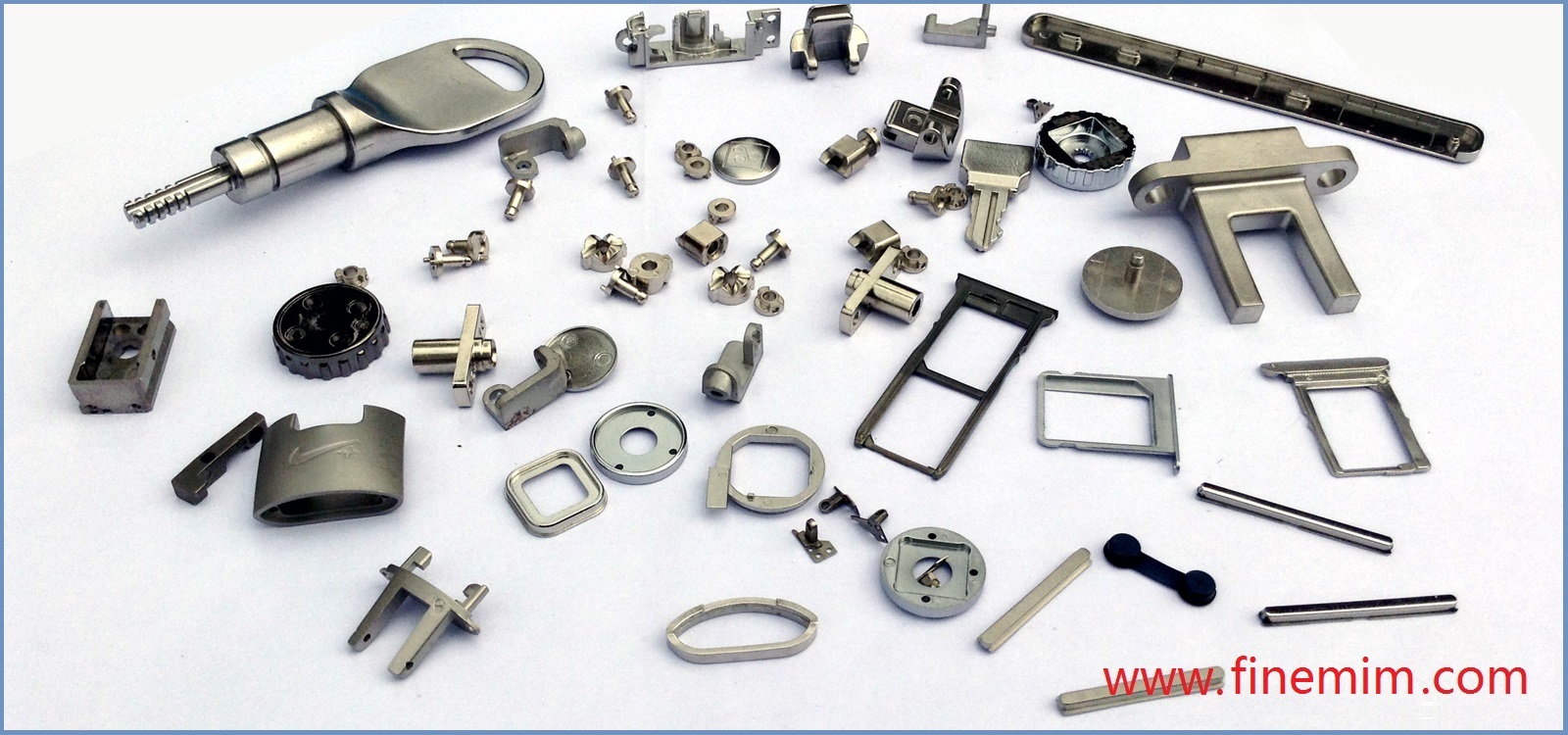

FineMIM has specialized in offering professional custom MIM parts manufacturing service in China for over 15 years. We provide one-stop solution for all MIM parts requirements including part design, tooling, prototyping, manufacturing, project management, and logistics. MIM products are widely used in consumer electronics, automotive, medical devices, hardware, tools and other fields. Our MIM factory is able to supply our customers around the world with medium and large quantities of complex metal parts at very competitive prices. More than 50% of our products are exported to Japan, South Korea, India, America and Europe.

Our company is devoted to become a leading one-stop supplier of MIM Parts and world-class solutions provider of Metal Injection Molding for our customers.